|

This white paper outlines a practical workflow for accelerating the scale-up of chemical processes from laboratory to commercial volumes. The approach leverages fully automated laboratory reactors (ALR), process analytical technology (PAT) like ReactIR™, and powerful data handling and modeling software (Scale-up Suite, including Reaction Lab™ and Dynochem®).

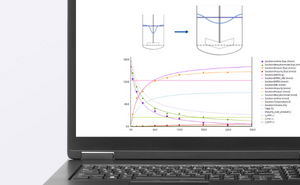

By conducting data-rich, small-scale experiments and using the generated data to build predictive kinetic models, process chemists can optimize process parameters for larger scales, ensuring safety, robustness, high yields, and efficient reaction times. The paper demonstrates this methodology through the acid-catalyzed hydrolysis of acetic anhydride, showcasing the accurate prediction of mixing equivalence, reaction kinetics, and safe addition times during scale-up to a 3 L jacketed lab reactor. This integrated approach minimizes risks, reduces labor, and material supporting Quality by Design (QbD) principles for efficient and reliable chemical process development.