Lab Pharmaceutical Quality Control Guide

The Lab Pharma Quality Control Guide shows you how to uphold peptide drug quality during development and manufacturing. Download it to start your journey towards improving your quality and efficiency.

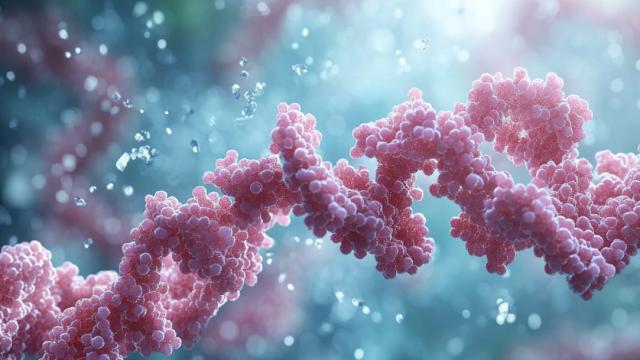

Peptide therapeutics are rapidly reshaping the pharmaceutical landscape, offering exceptional target specificity, low toxicity profiles, and the ability to modulate complex biological pathways. From metabolic diseases to oncology, peptides such as insulin, GLP-1 agonists, interferons, or enzyme therapies are enabling precision medicine across a wide spectrum of diseases and healthcare challenges.

While the therapeutic potential of peptides is well-established, manufacturing them at a commercial scale introduces significant process and infrastructure challenges. Whether chemically synthesized or biotechnologically expressed, peptide manufacturing faces including low-yield, multi-step complex syntheses, batch inconsistencies, scale-up difficulties from lab to GMP production, and strict quality control requirements, all while striving to meet stricter regulatory and sustainability standards. These constraints can delay product availability, strain supply chains, and ultimately impact patient access to critical therapies.

To support the growing demand for efficient and scalable peptide synthesis, METTLER TOLEDO offers a comprehensive suite of advanced precision instrumentation, machinery, and software solutions to ensure quality and precision at every stage of the production process.

The Lab Pharma Quality Control Guide shows you how to uphold peptide drug quality during development and manufacturing. Download it to start your journey towards improving your quality and efficiency.

Peptide production relies on advanced biochemical synthesis using solid-phase peptide synthesis (SPPS) for short peptides, while for larger, more complex molecules requiring post-translational modification, bioprocesses using recombinant protein expression systems, or a combination of bioprocesses and biochemical synthesis are the system of choice to ensure purity, potency, and consistency.

1. A peptide is built step-by-step by adding amino acids in a precise sequence on a solid resin.

2. After each addition, excess chemicals are washed away and protective groups are removed to prepare for the next step.

3. The finished peptide is cleaved from the resin and purified, typically using HPLC.

4. The purified peptide is turned into a solid or liquid product. Quality control tests are run throughout to ensure purity, safety, and effectiveness.

1. Peptide-producing bacteria or yeast are grown in a nutrient-rich medium optimized for high yield.

2. Peptides are separated from the culture using centrifugation and filtration. If inside cells, the cells are broken open first.

3. Peptides are purified using techniques like chromatography and tangential flow filtration, followed by any necessary cleavage or modifications.

4. Excipients are added, and the product is tableted or filled into vials, under sterile conditions. Quality control tests ensure purity, safety, and functionality.

Biochemical synthesis is a widely adopted method for peptide production, especially for short peptide production, and offers advantages over recombinant biological methods, in certain use cases:

Whether produced through biochemical synthesis or recombinant biological methods, peptide manufacturing remains inherently expensive. Each approach comes with its cost drivers, from reagent and solvent use in chemical synthesis to complex infrastructure and long production cycles in biological expression. As a result, there is a strong drive across the industry to maximize process efficiency, minimize variability, and ensure consistent product quality at every scale.

Flexibility: It allows the incorporation of non-coding amino acids and diverse backbone modifications to improve stability.

Purity: Chemical synthesis avoids the risk of host-cell contaminants and enables precise control of the product. However, recombinant methods also achieve high purity with proper downstream processing.

Recombinant biological approaches are common for larger proteins requiring complex post-translational modifications, and are advantageous for peptide production in circumstances such as:

Complexity: Biological methods enable complex peptide folding and specific post-translational modifications compared to chemical methods.

Sustainability: Chemical methods use an excess of high-purity, expensive reagents and solvents to ensure reaction completion, leading to greater chemical waste, and could affect global supply chains for essential solvents.

Peptide Length: Biological methods are better suited for producing longer peptides (>50 amino acids).

Many peptide APIs are developed through solid-phase peptide synthesis (SPPS), a stepwise process that allows precise control over sequence and modification. Others, particularly more complex or longer-chain peptides, are expressed in biological systems using microbial or mammalian cells.

While these methods differ in scale and platform, they share a need for rigorous process control and accurate material handling at every stage.

Whether weighing amino acids, solvents, or reagents in the R&D lab or handling kilogram-scale batches in production, accuracy in every measurement matters. Minute variations can affect:

METTLER TOLEDO provides robust weighing solutions for both laboratory and industrial applications. From microbalances that support formulation development to floor scales used in production suites, our equipment delivers the precision and compliance pharma manufacturers require. Integration with software systems also helps ensure full traceability and minimizes manual documentation errors.

Solid-phase peptide synthesis (SPPS) remains the gold standard for producing short to medium-length peptides, including therapeutic APIs like GLP-1 analogues or calcitonin. However, SPPS workflows can be complex, involving:

Understanding the progress of peptide coupling reactions is critical. In-situ FTIR and Raman spectroscopy tools by METTLER TOLEDO provide real-time insight into each step of synthesis, allowing scientists to monitor deprotection and coupling reactions, identify incomplete reactions early, and reduce overuse of costly reagents.

Controlling temperature, stirring, and reagent addition precisely across different synthetic steps using Automated Reactors such as EasyMax™ and OptiMax™ helps with the optimization of reaction conditions, the development of a safe scale-up from milligrams to kilograms, and the achievement of high reproducibility for tech transfer.

pH control is critical for peptide cleavage and purification. METTLER TOLEDO provides InPro series sensors that are tailored for use in harsh solvents, ensuring robustness and regulatory compliance during acidic cleavage or basic wash steps.

Many peptides, especially interferons, enzymes, or fusion peptides, are produced using recombinant technologies in microbial or mammalian systems. These processes require strict environmental control and real-time monitoring to maintain cell viability, protein expression, and product quality.

pH, dissolved oxygen (DO), CO₂, and conductivity must be precisely controlled during fermentation. ISM sensors from METTLER TOLEDO provide reliable real-time measurements, predictive diagnostics, sensor lifecycle management, and integration with PAT (Process Analytical Technology) strategies.

Once synthesized or expressed, peptides undergo multiple steps of purification and formulation before reaching their final drug form. Reverse-phase HPLC, ultrafiltration, and lyophilization are common techniques used to achieve the purity and stability required for therapeutic use.

Accurate preparation of buffers, solvents, and excipients is critical at this stage. Inconsistent concentrations or pH deviations can reduce recovery or compromise product stability. Whether during ultrafiltration prep, final formulation blending, or freeze-drying optimization, precision and reproducibility are non-negotiable.

Weighing equipment, pH meters, and UV/Vis spectrophotometers integrated into lab or production environments enable reliable downstream execution and QC in peptide manufacturing. Importantly, when the generated data is centrally collected and managed, it strengthens traceability and supports regulatory documentation.

Additionally, high-precision moisture analysis and water content determination by KF titration support final formulation and stability testing, key in freeze-dried peptide products. Whether during development or commercial QC, laboratory software solutions ensure consistent analytical data for required regulatory compliance and product quality.

From initial amino acid weighing to final vial inspection, each step in the peptide production journey demands precision. As products near release, automated product inspection systems serve as a critical safeguard before products leave the facility. For peptide therapeutics, this includes:

Physical contamination detection: X-ray inspection, metal detection or both to identify and remove physically contaminated products before entering the market.

Fill level control: Checkweighing, vision inspection and X-ray inspection monitor, measure and regulate fill levels to meet strict dosage and regulatory specifications.

Quality and integrity checks: Checkweighing, vision inspection and X-ray inspection perform integrity checks to help ensure pharmaceutical packages meet regulations and deliver safe, complete products to consumers.

Label quality inspection: Vision inspection for label quality control to detect label-related defects and mitigate the risk of product recalls.

Product Inspection solutions from METTLER TOLEDO are designed for high-efficiency pharmaceutical environments, offering:

GMP-compliant systems that integrate easily into existing lines.

Traceable performance verification for audit-readiness.

Support during the specification and qualification process, from evaluating the right application, selecting suitable product testing equipment and professional installation through to dedicated Equipment Qualification packs (EQpack) for efficient validation processes.

These systems not only protect product quality but also strengthen brand integrity and support regulatory compliance with agencies like the FDA, EMA, and global health authorities.

METTLER TOLEDO offers a range of instruments, software, and a global service network to help tackle the key challenges in therapeutic peptide production, for both biochemical and biological processes, simplify and streamline complex workflows, reduce variability, and support data-driven decision-making across all stages of development and manufacturing. This helps in achieving higher yields, reduced waste, faster scale-up, and more reliable compliance, making the high-cost therapeutic peptide manufacturing more sustainable and patient access more achievable.

| Application or Parameter | What is to be measured? | Why is it measured? | METTLER TOLEDO Solution | Measurement Mode | |

Concentration and purity | Absorbance or transmittance | To determine the concentration and purity of peptides in both chemical (monitoring synthesis and purity) and biological (purification stage) production | Offline | ||

Inline | |||||

Cell count, biomass, morphology, and viability | Cell count and viability | Relevant in biological production to monitor microbial culture health and biomass, ensuring optimal conditions for expression | Atline | ||

Biomass and morphology | Inline (SIP or CIP) | ||||

Characterizing cellular and biochemical parameters | Absorbance or transmittance | Used primarily in biological systems to assess metabolic activity, protein expression, and toxicity | Offline | ||

Inline | |||||

pH | pH | Critical for microbial cell growth and optimal enzyme function during fermentation in biological production. pH must also be carefully monitored and optimized to ensure efficient coupling reactions for chemical synthesis | pH meter and | Atline Inline | |

Residual moisture content | Water content determination | Residual moisture must be tightly controlled to ensure stability and shelf life, especially post-lyophilization | Offline | ||

Dissolved oxygen | Dissolved oxygen level | Ensures sufficient oxygen for microbial respiration during fermentation in biological production. Moreover, it helps mitigate hazardous levels of oxygen in contact with combustible gas phases and organic solvents. Also ensures oxygen mitigation through nitrogen blanketing in fill & finish | Inline | ||

Conductivity | Conductivity | Helps assess medium composition and ionic strength along with dissolution, relevant in both biological media and chemical synthesis buffers | Inline | ||

CO2 accumulation | Dissolved CO2 level | Monitors CO2 buildup during biological fermentation, guiding aeration and feed strategies | Inline | ||

Turbidity | Turbidity (NTU) or image-based turbidity | Provides information on microbial culture expansion and potential contamination in biological systems | Turbidity sensor EasyViewerTM | Inline | |

Optical density | OD 600 | Used in biological production to track microbial growth phase and expression levels. Crucial for determining optimal timings for induction and harvesting | Offline | ||

Glucose | Enzymatic determination with UV/Vis | Monitors nutrient levels (e.g., glucose) in biological fermentation to optimize cell growth and peptide yield | Offline | ||

Absorbance or transmittance | Inline | ||||

Weight | Mass | Accurate and precise sample preparation | Offline | ||

Weight | Mass | Statistical Quality Control (SQC) to ensure accurate filling, weight and process compliance | Offline | ||

Weight or Volume | Mass | Ensures accurate component addition during both chemical synthesis (reagents) and biological media preparation | Atline Inline | ||

Weight or Volume | Mass | Ensure accurate addition of alkaline solution for pH control of the bioprocess Ensure accurate feed addition in fed batch and continuous culture Accurate monitoring of media removal in continuous culture Accurate monitoring of bioreactor volume to avoid overflow Accurate Fill & Finish | Weighing Controllers and Transmitters Ultra-Low-Profile Hygienic Floor Scales | Inline | |

Temperature | Temperature | Maintains optimal reaction or fermentation temperatures, critical for both synthesis and microbial expression | |||

Pressure | Pressure | Controls fluid flow and reaction pressure in reactors used in both synthesis and bioprocessing | Inline | ||

Process optimization and scale-up | Biochemical | Synthesis reactor | To control and optimize all critical process parameters, reduce variability | ||

Process modelling | To model reaction kinetics, product isolation, and more to enable robust scale-up | ||||

Precipitation optimization | To assess particle size and control temperature | ||||

Reaction sampling | To assess reaction progress and enable optimizations | ||||

System monitoring | System monitoring | System monitoring | |||

Process development | To integrate design space and reactor parameters with PAT information for scalable process design | ||||

Reaction analysis | To assess real-time reaction dynamics for process optimization | ||||

Biological | Harvesting or particle size or precipitation | To assess the progress and completion of reactions | |||

Process modelling | To model reaction kinetics, product isolation, and more to enable robust scale-up | ||||

Product quality inspection | Physical contamination detection, fill level and weight control, package integrity, and completeness checks | To support a safe and complete product for the end customer, avoid product recalls and litigation, and achieve vital packaging compliance for the manufacturers | |||