Didn’t Find a Matching Balance? Explore Our Other Balance Types:

Advantages

Do You Want Your Balance to Perform at Its Best? Get It Serviced by the Market Leader

Do You Want Your Balance to Perform at Its Best? Get It Serviced by the Market Leader

FAQs

What is a microbalance and what is an ultra-microbalance?

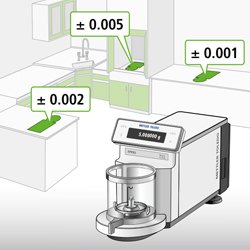

Micro balance vs analytical balance. What is the difference?

What is a microbalance used for?

What is special about microbalance design?

Which micro weighing balance is right for me?

Where should I place the micro balance in my laboratory?

How to weigh on a microbalance?

How can I ensure stable readings on my micro balance?

What is the safest way to weigh toxic and potent substances on a microbalance?

How to clean a microbalance?

How do I calibrate and adjust my microbalance? What about microbalance routine testing?

How can I save my results and the data from my microbalance?

How do I transfer data from the XPR microbalance to a computer?

How do our microbalances contribute to sustainability?

What types of weighing pans and accessories are available for XPR microbalances?

Why Is calibration of microbalances important?

Is an external microbalance required for thermal analysis?

Can I weigh filters (automotive or environmental) on Mettler Toledo’s microbalances?

Can I weigh stents on METTLER TOLEDO microbalances?

What is the importance of using a draft shield on a microbalance?

How should I store a microbalance when not in use?

What does USP General Chapter 1251 say about safety factors for weighing?

USP Chapter 1251 introduced concrete safety factor values for the first time in 2025: a safety factor of 2 is recommended for stable laboratory conditions with trained operators, while a safety factor of 1.5 applies to automated weighing procedures where environmental and operator influences are minimized. Monitoring the safety factor throughout the balance's lifecycle helps identify critical performance changes.

How can a microbalance help me meet USP General Chapter 41 compliance requirements?

Microbalances provide significant advantages when complying with USP Chapter 41 requirements, especially regarding the safety factor. Because microbalances can accurately measure very small sample weights with exceptional repeatability, they enable laboratories to work with lower smallest net weights. This directly impacts the safety factor, which is defined as the ratio of the smallest net weight to the minimum weight. With the ability to reliably weigh smaller amounts, microbalances can achieve a lower minimum weight, which improves the safety factor value and helps to meet or exceed USP Chapter 1251 recommendations. Microbalances support tighter control over weighing accuracy and safety, ensuring compliance with USP Chapter 41 and reducing the risk of critical performance deviations over the balance’s lifecycle.

What are the calibration requirements for balances according to USP General Chapter 41?

Balances must be calibrated with the inclusion of measurement uncertainty and on a risk-based periodic schedule. Calibration is required before and after any operation that could significantly affect measurement performance, known as “as found” and “as left” calibration, ensuring accurate and compliant weighing results. The MT GWP® Verification service and the ACC calibration certificate help you determine and ensure that all your balances are reliable enough during routine operation.