Visit the Product Inspection experts to see live demonstrations of solutions that can help you increase productivity, boost profits, combat rising manufacturers' costs, and protect brand reputation. Our full range of metal detectors, checkweighers, vision and x-ray inspection systems with customized material handling solutions deliver unmatched inspection capability on all types of bulk and packaged products.

Depending on your specific requirements, systems can detect solid contaminants, verify product weights, ensure the accuracy and integrity of packaging and labels, confirm component content, inspect closures, and measure fill levels.

10/01/2025 3:00pm, PST

Las Vegas, Nevada 89109

Booth W2122

Mon, 9/29: 9am - 5pm

Tue, 9/30: 9am - 5pm

Wed, 10/1: 9am - 3pm

See Live Music, Educational Presentations, and Live Demonstrations on the Latest Product Inspection Solutions for a Variety of Applications!

Our experts will demonstrate a wide range of product inspection solutions for contamination detection, integrity checks, fill level accuracy, and label content and quality verification.

Highlights of Product Inspection Solutions:

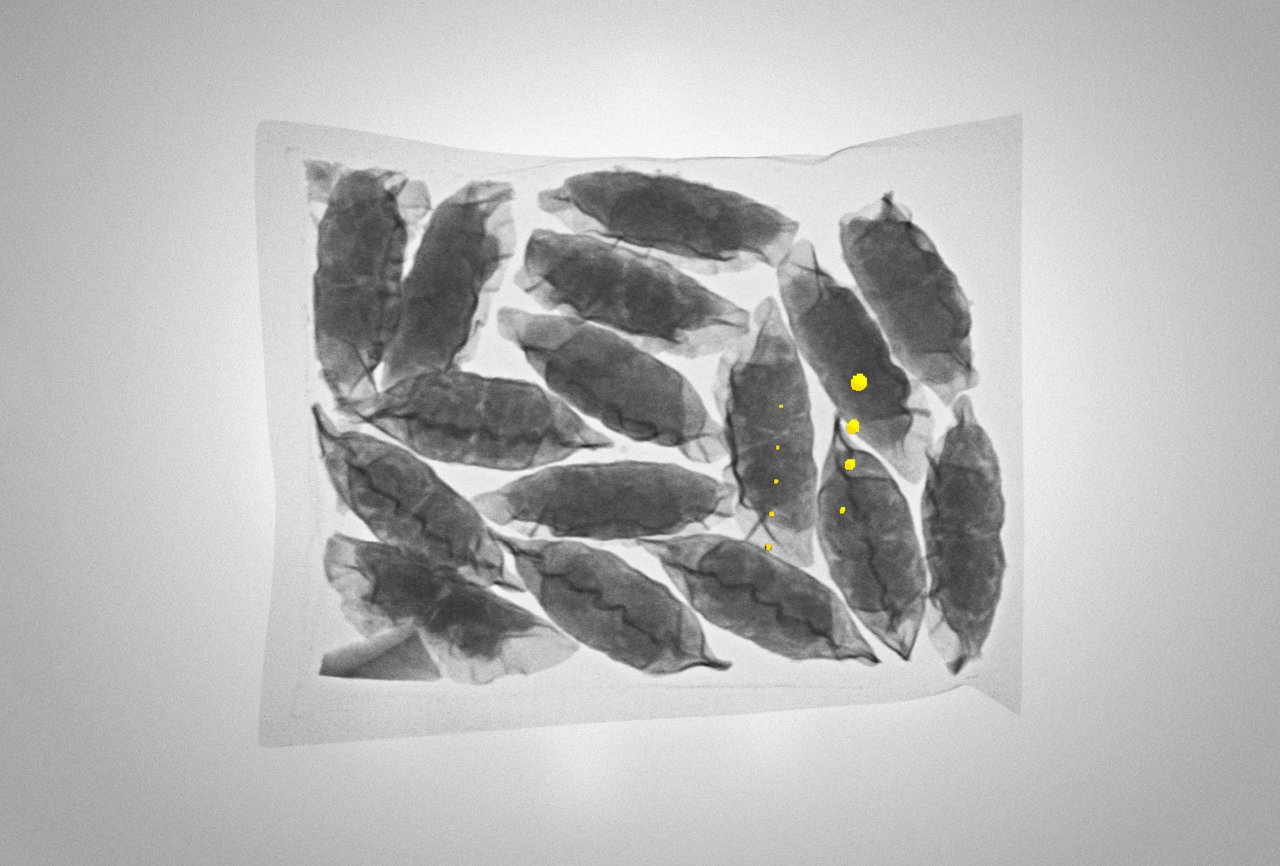

- The Latest in X-ray Inspection

Among several x-ray systems, we will introduce a new x-ray inspection system for bulk flow applications which provides outstanding contamination detection beyond metal, including glass, stone, bone, and high density plastics and rubber. This new system will help food producers inspect products early in the process, significantly reducing the amount of product waste as well as protecting upstream equipment to ensure the production line keeps running.

- True Mix and Match Combination Inspection Systems

We will show a variety of combination systems: checkweigher/vision, checkweigher/x-ray, and checkweigher/metal detector. Systems are now available in all types of configurations and price points, including an all-in-one checkweigher/vision/x-ray/metal detector system. - Metal Detection Systems for all Budgets and Applications

We will showcase metal detection systems for pharmaceutical, piped, gravity feed, and conveyorized applications. See live demonstrations of metal detectors on the affordable SL1000 conveyor as well as on the SL2000 meat + protein conveyor. For gravity feed applications, learn about Automatic Test System (ATS) which allows for routine performance monitoring testing to be performed in less than one minute.

- Vision Inspection of Labels Directly After Printing

We will showcase a variety of vision systems for the V31 vision system combined with a thermal transfer printer which inspects labels immediately after printing for the integrity of graphics, reading & verifying 1D and 2D codes, and alpha-numeric characters utilizing OCV/OCR tools.

- Live ProdX™ Connectivity and Data Management

We will demonstrate the latest version of ProdX connected to multiple systems in the booth. ProdX is based on Industry 4.0 principles of secure machine-to-machine communication and prepares connectivity to blockchain technology. The software can digitalize food safety compliance, reduce compliance auditing time and help facilitate faster product recalls.

Educational Presentations and Live Music Schedule

Monday, 9/29

10:00am - 10:15am Metal Detection, X-ray Inspection, or Both?

10:30am - 11:00am Live Music

11:15am -11:30am Solutions for Data Management of Product Inspection Systems

1:30pm - 2:00pm Live Music

2:30pm - 2:45pm Detecting Contamination: Single Energy Versus Dual Energy

3:15pm - 3:45pm Live Music

4:00pm - 4:15pm Benefits of Combination Inspection Systems

Tuesday, 9/30

10:00am - 10:15am All Eyes on X-ray for Big Box Retailers

10:30am - 11:00am Live Music

11:15am -11:30am Five Ways to Combat Rising Food Manufacturers' Costs

1:30pm - 2:00pm Live Music

2:30pm - 2:45pm Prevent Product Recalls with Automatic Vision Inspection

3:15pm - 3:45pm Live Music

4:00pm - 4:15pm Service Offerings to Consider When Purchasing Product Inspection Equipment

Wednesday, 10/1

10:00am - 10:15am Best Metal Detection Testing Practices

10:30am - 11:00am Live Music

1:00pm - 1:15pm ROI of Product Inspection Systems

Learn more about the sessions and speakers >

|