Resin quality hinges on a reliable measurement of softening behavior—yet resins are notoriously tricky, with no defined melting point and gradual transitions from solid to plastic states. In today’s environment of stringent performance requirements and uniform product expectations, having a trustworthy softening point (SP) method in resin analysis is critical. This article explores two widely accepted approaches—METTLER cup-and-ball (ASTM D 6090 / ISO 4625-2) and ring-and-ball (ASTM D 6493 / ISO 4625-1)—to see how they stack up in determining SP across a variety of phenol-based resins. We delve into correlation, repeatability, and how these methods fare in different temperature ranges, offering insights to help labs confidently maintain resin quality.

|

Figure 1. Resins in handcraft. |

When it comes to the characterization of softening behavior in phenol-based resins, manufacturers often face significant challenges due to the lack of well-defined melting points. Understanding the precise transition from a solid-like state to a more plastic, flowable condition is vital for controlling viscosity, optimizing production processes, and ensuring consistent quality in end products. This article focuses on comparing two widely recognized methods for measuring the softening point (SP) of resins: the Mettler cup-and-ball method (ASTM D 6090 / ISO 4625-2) and the ring-and-ball method (ASTM D 6493 / ISO 4625-1).

In our study, we tested a range of phenolic resins using both techniques to evaluate their effectiveness in determining softening points, particularly within the critical temperature range of 60–150 °C. Each method operates differently, utilizing specific equipment to achieve reliable results. For the Mettler cup-and-ball method, we employed the METTLER TOLEDO Excellence Dropping and Softening Point System, including a variant test that did not use the conventional steel ball. In contrast, the ring-and-ball method was executed using automated instruments from KOEHLER.

Accurate softening point measurement is essential for resin quality control, particularly in today's industries that enforce stringent performance requirements. The gradual transition from solid to plastic state in phenolic resins complicates this process, making a trustworthy softening point analysis indispensable. By investigating the correlation and repeatability of results from both methods, this article aims to provide valuable insights for laboratories to confidently maintain resin quality, ultimately benefiting product reliability and performance across various applications.

When to Compare Cup-and-Ball vs. Ring-and-Ball

Resin manufacturers regularly grapple with the elusive nature of softening behavior, especially for phenol-based formulations. Determining the precise transition from a solid-like state to a more plastic flow is essential for controlling viscosity, production conditions, and end-product consistency. In this spotlight, we evaluate two industry-recognized approaches for measuring softening points:

- METTLER Cup-and-Ball (ASTM D 6090 / ISO 4625-2)

- Ring-and-Ball (ASTM D 6493 / ISO 4625-1)

After testing a suite of phenolic resins, we outline exactly how each method works, what equipment is used, and—most importantly—how their results compare across the crucial 60–150 °C range.

|

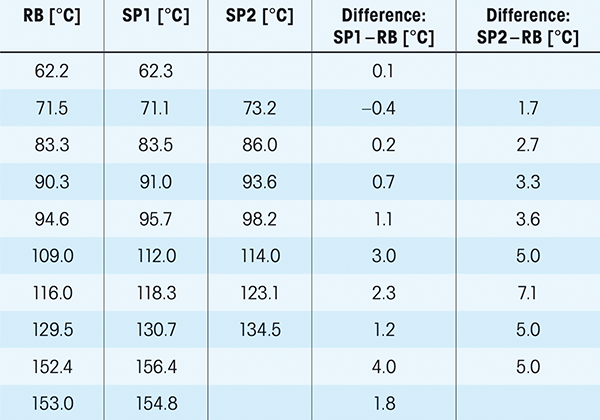

Figure 2. Video-recorded softening point event at 90.5 °C (left) of two resin samples in the DP70. |

Applications

In conducting these head-to-head measurements, the research team employed:

- The METTLER TOLEDO DP70 Excellence System for the cup-and-ball technique (including a variant test without the usual steel ball).

- KOEHLER automated instruments for the ring-and-ball procedure.

Softening Point: Why It Matters

Phenol-based resins don’t have a well-defined melting point. Instead, they soften over a range, transforming from a pseudo-solid into a more pliable state. Knowing the exact temperature of this shift impacts everything from raw material acceptance to final product QC—particularly in industries that demand uniform performance and reliability.

METTLER Cup-and-Ball Method

Procedure:

- A brass or aluminum cup (with a 6.35 mm aperture at the base) is filled with resin.

- A 2.77 g steel ball (8.7 mm diameter) is placed atop the sample.

- From 30 °C below the expected SP, the sample is heated at 2 °C/min. Once the resin flows 19 mm below the cup, the temperature recorded is the softening point.

Instrumentation:

- The DP70 Excellence Dropping and Softening Point System can analyze two samples at once. Its patented video technology also allows for replay, making it easy to confirm when the resin truly passes through the aperture.

Variation:

- Some runs were performed without the steel ball—referred to as “SP2.” This influenced correlation with ring-and-ball data, an important factor for labs deciding whether or not to impose additional weight.

|

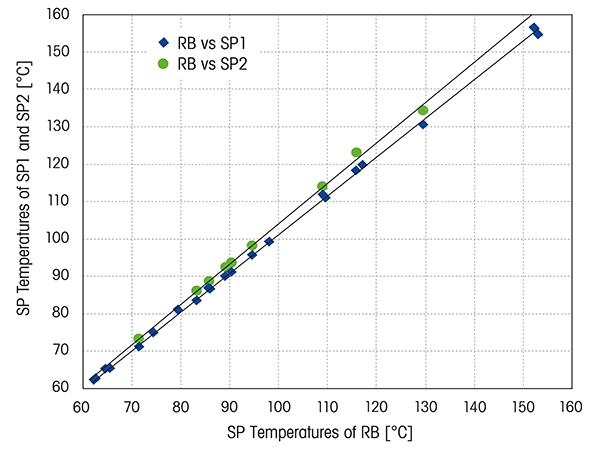

Table 1: Typical softening point result of the two methods. RB: Ring-and-ball, 4 °C/min heating rate. SP2: METTLER Method without ball, 2 °C/min heating rate. |

|

Figure 3: Linear correlation between RB vs SP1 and RB vs SP2 resin softening point (SP) tests. |

Ring-and-Ball Method

Setup:

- A brass ring is packed with resin and suspended 25 mm above a metal plate in a heated bath (water, glycerol, or silicone oil).

- A steel ball (~3.5 g) sits on top of the resin.

- Heating typically proceeds at 4 °C/min until the resin becomes soft enough for the ball to drop, contacting the plate below.

Correlating the Results

Phenol-Based Resins Tested: 60–150 °C

- Close Agreement (SP1 vs. RB): Up to 100 °C, the METTLER cup-and-ball method (with steel ball) and ring-and-ball align closely, staying within repeatability and reproducibility limits. Even at higher SPs, discrepancies typically remain within ±3 °C—an acceptable tolerance for most QC programs.

- Impact of No Ball (SP2): The correlation becomes notably weaker if the steel ball is omitted, suggesting that consistent loading is vital for accuracy.

- Heating Rate Effects: Both approaches find that heating at 2 °C/min is suitable for loaded cup-and-ball samples. However, slower rates might be advisable if no ball is used, to capture the resin’s transition more precisely.

Conclusions and Practical Relevance

- Method Parity: In the 60–150 °C range, a cup-and-ball test with the steel ball (SP1) delivers nearly the same SP values as ring-and-ball.

- The Role of Weight: Omitting the ball (SP2) drives up variance, indicating that uniform load application is crucial for consistent data.

- Future Considerations: Slower heating could enhance outcomes for unweighted setups, and further research might reveal whether a ball is strictly needed above 100 °C.

References

- European Patent 2565633, March 6, 2013.

- R. Mildenberg, M. Zander, G. Colin, Hydrocarbon Resins, VCH Verlagsgesellschaft, 1997, ISBN 3-527-28617-9.

- European Patent 2564927, March 6, 2013.

Learn More and View Our Instruments

For deeper insights and videos, visit:

|

Ewa Ziółkowska |

Ewa Ziółkowska is a Product Manager at METTLER TOLEDO, specializing in Physical Values.

With a degree in Biotechnology Engineering and over five years of experience spanning customer support, product management, and application development, Ewa collaborates with cross-functional teams to refine analytical solutions, ensuring they address evolving market needs.