In an era where laboratories are expected to deliver results faster and with unwavering accuracy, the need for reliable software solutions has never been greater. From complex data management to strict regulatory demands, labs must innovate efficiently while adhering to compliance requirements. METTLER TOLEDO’s new range of compliance-focused laboratory software solutions aims to transform this landscape—enabling seamless connectivity, centralized control, and real-time insights that help labs thrive in competitive industries.

|

Laboratory Software Solutions

METTLER TOLEDO has long been at the forefront of developing software solutions to streamline and integrate laboratory operations. Whether in chemical, pharmaceutical, biotech, food, or academic environments, these platforms seamlessly connect instruments and data flows. The result? Secure, digital data management, connectivity with instruments and other software systems (e.g. LIMS, ELNs), and digitalized and efficient workflows - all leading to significant cost savings and efficiencies.

Why Compliance Matters

Today’s regulatory environment demands stringent data integrity and reliable audit trails. METTLER TOLEDO’s compliance-focused software solution delivers these requirements by ensuring that all data is captured electronically, and is fully secure and traceable, at every step. The electronic capture of data vastly reduces transcription errors and ensures that the data is ready for review and auditing at any stage.

|

Figure 1: METTLER TOLEDO enables seamless connectivity between lab instruments, data management and instrument control software and LIMS systems. |

The Power of Integration

Instrument integration with LIMS, ELN, or ERP systems is important for delivering complete metadata and preventing gaps in compliance. While direct connections to enterprise systems capture basic information, METTLER TOLEDO`s software ensures your data is both comprehensive and regulatory-ready. By consolidating asset management, instrument control, and secure data capture, you stand to significantly reduce errors and speed up critical processes.

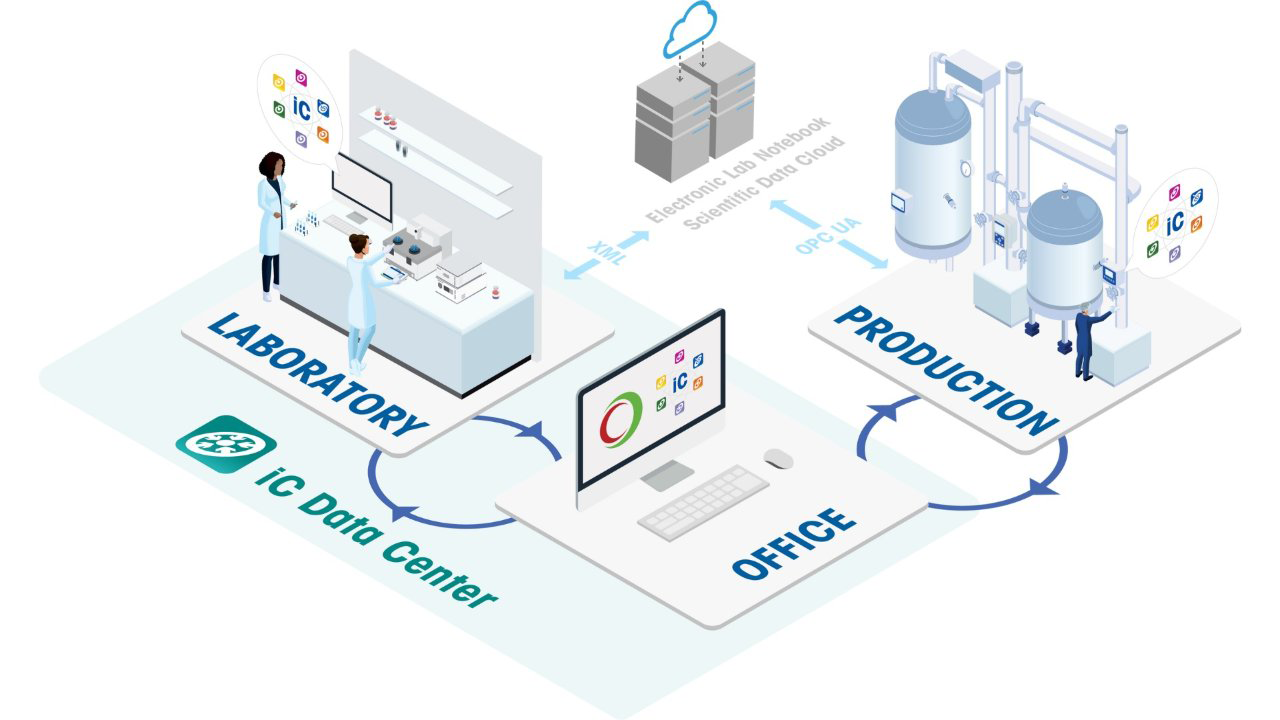

Lab-to-Production Software

For organizations looking to scale their developments beyond the lab, METTLER TOLEDO’s solutions like iC Data Center, Dynochem, and Reaction Lab™ offer advanced capabilities. These systems enable real-time collaboration and data analysis, providing the clarity necessary for consistent, high-quality production runs. By simulating reactions, predicting scale-up challenges, and integrating experiment workflows, they help drive innovation from R&D through manufacturing.

|

Figure 2: iC Data Center links lab results to office dashboards and live production control for effortless compliance. |

Benefits at a Glance

- Streamlined Workflows: Eliminate inefficient manual steps through centralized, automated electronic data capture. This reduces transcription errors and accelerates analysis and decision-making.

- Data Integrity and Enhanced Compliance: Ensure adherence to ALCOA++ and regulations such as 21 CFR Part 11 with robust audit trails, secure data storage, and comprehensive user authentication. All data is transmitted and stored electronically for maximum traceability.

- Reduced Costs: Save money through faster batch releases, minimized process deviations, and fewer errors—all enabled by automated workflows and consistent data handling.

- Improved Accessibility: Access instrument data, maintenance statuses, and the results of experiments in real-time—from anywhere—via a unified digital platform that supports secure remote collaboration.

Conclusion

METTLER TOLEDO’s laboratory compliance software is more than just a data management tool—it’s a strategic investment in your lab’s future. By offering seamless integration with existing networks and enterprise systems, these solutions reduce overhead, expedite workflows, and help ensure that regulatory standards are continuously met. Whether you manage a single workstation or a global lab network, these software solutions position you for ongoing success in an industry where reliable data and consistent compliance are paramount.

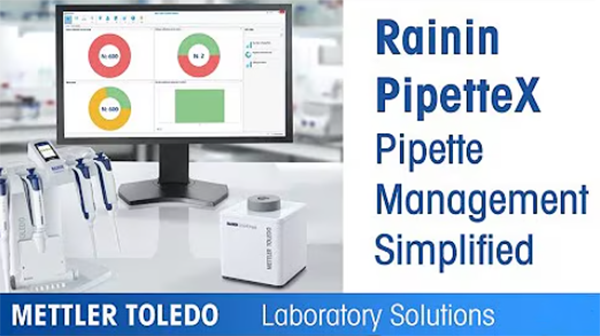

1. PipetteX Asset Management Software

- Automates the upkeep of service, calibration, and recordkeeping for all pipette brands.

- Less administrative hassle means your team can focus on high-value tasks rather than routine checks.

- Learn more

|

|

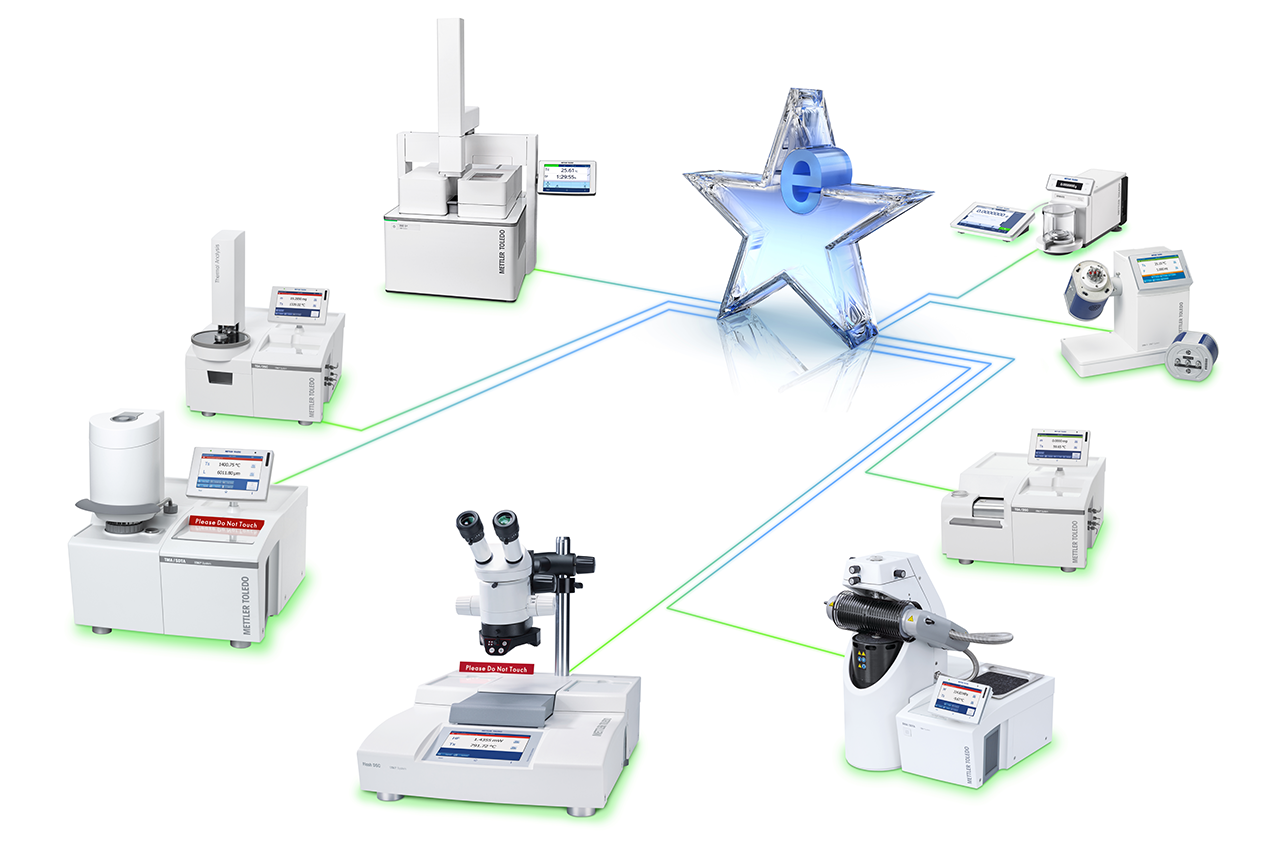

2. LabX™ Laboratory Software

- Fully networks key METTLER TOLEDO instruments, enabling real-time electronic data capture and digitalized method management.

- Streamlines workflows by eliminating manual data entry, reducing the need for training and review and speeding up analysis.

- Learn more

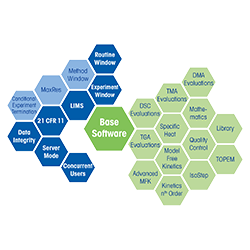

3. STARe Excellence Thermal Analysis Software

- Offers unparalleled flexibility for modern thermal analysis systems.

- Helps maximize productivity by providing advanced data evaluation and reporting features.

- Learn more

|

|

Nuala Nic Ghearailt |

Nuala Nic Ghearailt, Marketing Manager for LabX at METTLER TOLEDO, helps labs boost efficiency, productivity, and compliance through digitalization.

With a background in marketing, sales and strategy management consulting, Nuala brings a strategic overview to our go-to-market approach, while also being able to translate complex concepts into informative communication campaigns.