Data-Driven Modeling for the Enhanced Understanding of the Crystallization of an Active Pharmaceutical Ingredient

Crystallization Modeling in Pharmaceutical Manufacturing

Program oversigt

- Crystallization modeling

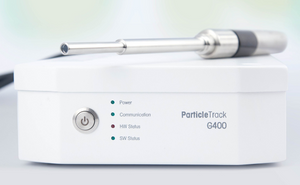

- Automated solubility data collection using PAT

- Dynamic response surface modeling (DRSM)

In this study, we developed a data-rich experimentation workflow that can be used to characterize and model the dynamic behavior of an antisolvent crystallization on an active pharmaceutical ingredient (API). First, automated, parallel experiment technology and empirical models are used to describe the API solubility as a function of temperature and solvent composition. Next, an efficient protocol that leverages laboratory automation and process analytical technology (PAT) was used to generate an accurate chemometric model that quantifies API supernatant concentration with in-situ FTIR spectroscopy. Using a 2^2 full factorial design and data-rich experimentation (DRE), supernatant concentration profiles were obtained to characterize the impact of crystallization temperature and antisolvent charge rate on the isolation procedure.

These multivariate, time series data profiles were subsequently modeled using Dynamic Response Surface Methodology (DRSM). This provides a comprehensive understanding of the sensitivity of the operation and highlights how the combination of DRE and process modeling can lead to valuable process knowledge for optimization and control strategies for crystallization in pharmaceutical manufacturing.

Speakers

Andrea Angulo

Sr. Scientist, Merck

Ph.D. in Chemical Engineering from New York Univeristy (2023). Postdoctoral Research Associate, Chemical Engineering R&D, Merck (2023-2024). Sr. Scientist, Chemical Engineering R&D, Merck (2024-Present)