Pharmaceutical suspensions bring unique obstacles to pH measurement—clogged sensors, extended setup times, and even incomplete data. These risks multiply when dealing with heavily regulated products where compendial methods such as USP guidelines must be followed. In this article, discover how the specialized InLab® Max Pro-ISM sensor from METTLER TOLEDO offers a solution tailored for accurate, efficient pH testing in suspensions like Oxcarbazepine, Ibuprofen, and Triamcinolone Acetonide.

By reducing sensor response time and maintaining stable readings, labs can streamline QC workflows without compromising on compliance or reliability.

The Challenge of Measuring pH in Suspensions

Pharmaceutical suspensions, whether they’re lightly dispersed or heavily particulate, pose unique challenges to standard pH electrodes—clogged junctions, slow response times, and inconsistent readings. This can lead to data gaps, wasted operator time, and potential noncompliance, especially if your products must align with USP guidelines for accuracy and documentation.

The Right Sensor Choice: InLab Max Pro-ISM

|

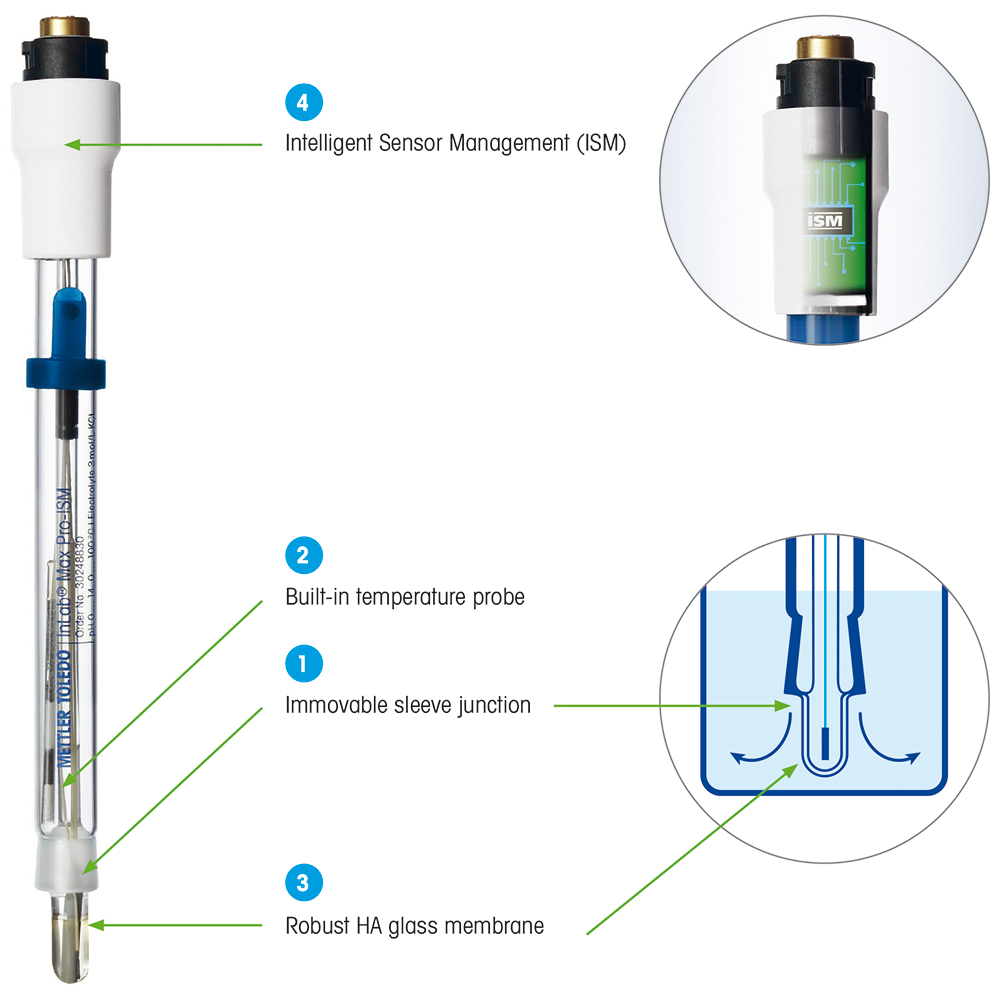

Figure 1. InLab Max Pro-ISM sensor. |

1. Clog-Resistant Junction

An immovable sleeve design minimizes blockages, ensuring that complex or particulate samples flow around the electrode consistently. This preserves the sensor’s lifespan and promotes steady data collection.

2. Integrated Temperature Probe

Especially vital under compendial methods (e.g., USP monographs), accurate temperature compensation reduces the risk of measurement drift. The probe is built right into the sensor, making external equipment or extra wires unnecessary.

3. HA Glass Membrane

This chemically resistant membrane stands up to higher pH or temperature ranges, which is crucial for robust pharma formulations.

4. Intelligent Sensor Management (ISM)

Calibration data, temperature history, and primary sensor information are stored directly on the electrode. This reduces transcription errors and helps labs maintain a traceable audit trail.

A Practical Workflow

In a published study, three different suspensions (Oxcarbazepine, Ibuprofen, and Triamcinolone Acetonide) were tested following USP monographs. The SevenExcellence benchtop meter paired with the InLab Max Pro-ISM sensor provided reproducible results at 25 ± 2 °C.

- Pre-measure Steps: Shake or stir each suspension thoroughly, ensuring uniform dispersion of any particles.

- Measurement: Immerse the sensor in 40 mL of sample, record both pH and temperature. Rinse with deionized water to avoid cross-contamination before proceeding to the next sample.

- Autosampler Option: An InMotion Autosampler can further automate the entire process, from stirring to sensor cleaning, slashing manual input and error risks.

Key Results and Observations

- Accurate Readings: Each measured suspension fell within its expected pH range, confirming alignment with pharmacopeial guidelines.

- High Consistency: Standard deviations were minimal (≤ 0.01 pH units in some cases), demonstrating the sensor’s reliability.

- Faster Response: Operators noted reduced measurement times compared to conventional sensors, crucial for labs dealing with large sample throughput.

|

Figure 2. pH measurement of Ibuprofen oral suspension. |

Best Practices for Long-Term Performance

- Regular Calibration: Use fresh METTLER TOLEDO buffers daily, ensuring slopes remain between 95–105% and offsets preferably below ±20 mV.

- Reconditioning: For sensors used in protein-laden suspensions, occasional pepsin HCl soaks help maintain an unclogged junction.

- Proper Storage: After use, store the electrode in a wetting cap with InLab Storage Solution; never let it dry out.

Conclusion & Relevance

The InLab Max Pro-ISM sensor stands out as a robust, precision-driven solution for pH measurements in complicated pharmaceutical suspensions—reducing response time, upholding USP standards, and improving day-to-day efficiency. By combining a clog-resistant design, integrated temperature compensation, and Intelligent Sensor Management, labs can tackle everything from simple oral suspensions to challenging multi-ingredient formulations. With minimal operator oversight, streamlined calibration, and traceable data logs, it’s a future-proof choice for any QC team committed to both accuracy and compliance.

|

Dr. Kajal Jaiswal |

Dr. Kajal Jaiswal is a Scientific Marketing Specialist at METTLER TOLEDO, bridging science and marketing with SEM-focused pH Lab support, aligning initiatives with evolving advancements

With a PhD in chemistry and extensive scientific writing experience, Dr. Jaiswal deeply understands both theoretical and practical aspects of the field. Her multidisciplinary approach translates complex data into actionable marketing insights, driving meaningful engagement with METTLER TOLEDO’s solutions.

|

Dr. Ajay Gopinathan |

Dr. Ajay Gopinathan is Deputy Manager – R&D and Projects SBU-pH Lab at METTLER TOLEDO, fostering innovation and providing effective solutions that align with the constantly evolving market trends and advancements.

Dr. Ajay holds a Ph.D. in Chemistry and has extensive experience in the pharmaceutical sector in delivering products for the global market. At METTLER TOLEDO, his work involves creating engaging application notes, managing a diverse range of R&D projects, and conducting dynamic testing, all aimed at delivering meaningful solutions.