Webinar – Thermal Analysis of Food

Characterizing Raw Materials and Finished Goods in the Food Production Industry

Program Overview

- Introduction

- Basic properties of food

- Typical questions

- Thermal analysis

- Industries and applications

- Instrumentation and applications

- Summary

Food, usually of plant or animal origin and containing important nutrients, is typically modified and made fit for consumption. Thermal analysis allows the study of physical and chemical effects related to temperature changes that occur during the normal food processing cycle, such as boiling, freezing, and drying. A better understanding of these processes is vital in the food industry.

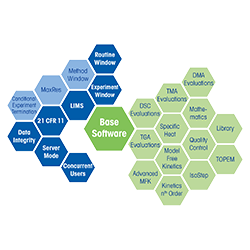

In this webinar, we will show how thermal analysis is used to analyze food and will present some typical examples of samples measured by Differential Scanning Calorimetry (DSC), Thermogravimetry (TGA), Thermomechanical Analysis (TMA), or Dynamic Mechanical Analysis (DMA)

In the webinar titled “Thermal Analysis of Food”, we describe a number of interesting application examples that demonstrate the use of thermal analysis techniques in fields such as food processing, food storage conditions, and food quality in various segments of the food industry.

A Highly Regulated Industry

Food products are directly linked to public health issues. As a consequence, various international and national regulations and laws exist, providing methods for checking the quality of food products.

Thermal analysis is nowadays an important technique for characterizing different materials in many fields of the food industry.

Thermal Analysis of Food

The most important effects that can be analyzed by DSC are melting point, melting range, and melting behavior. DSC is used to determine heat of fusion, purity, polymorphism, glass transition, and oxidation stability.

The main applications of TGA include evaporation, desorption and vaporization behavior, thermal stability, kinetics of decomposition, and compositional analysis.

TOA is used to study the melting point, melting range, and polymorphism using visual observation and the recording images and videos.

TMA is normally used to study the expansion or shrinkage of materials and the glass transition.

DMA is the most sensitive method for characterizing the glass transition of materials.